Introducing our state-of-the-art Hot & Cold Cutting Machine, a versatile apparatus that revolutionizes precise cutting applications across industries. This cutting-edge equipment seamlessly combines both hot and cold cutting methods, offering unparalleled flexibility for diverse materials such as plastics and textiles. Our Hot & Cold Cutting Machine is engineered to deliver clean, precise cuts, making it an indispensable tool in manufacturing processes. This dual cutting machine embodies the essence of advanced cutting technology, ensuring efficiency and quality in production while meeting the highest industry standards. Experience the power of innovation with a high-precision cutting machine designed to enhance precision and streamline your manufacturing workflows. Invest in the future of production technology with our Hot & Cold Cutting Machine. Stay at the forefront of efficiency and quality in your industry by incorporating this essential apparatus into your industrial cutting solutions. Discover the transformative capabilities of our multi-functional cutting machine, setting new standards for clean and accurate cuts in the production of a wide range of products. Whether you need versatile cutting solutions or require a machine that adapts to various materials, our Hot & Cold Cutting Machine guarantees superior performance. Upgrade your manufacturing processes today with this innovative cutting technology that ensures efficiency and quality across all applications.

Key Features:

- Dual Cutting Capability: Combines hot and cold cutting methods for versatility.

- Precision Engineering: Delivers clean, precise cuts across various materials.

- Advanced Technology: Ensures high efficiency and quality in manufacturing.

- Multi-Functional Design: Suitable for plastics, textiles, and more.

- User-Friendly Interface: Easy to operate and integrate into existing workflows.

Benefits

- Enhanced Productivity: Streamlines manufacturing processes, reducing downtime.

- Cost Efficiency: Minimizes waste and maximizes resource utilization.

- Versatility: Adapts to different materials, making it ideal for diverse applications.

- High-Quality Outputs: Meets industry standards for precision and reliability.

- Future-Proof Investment: Keeps your operations at the forefront of cutting technology.

Introducing our state-of-the-art Hot & Cold Cutting Machine, a versatile apparatus that revolutionizes precise cutting applications across industries. This cutting-edge equipment seamlessly combines both hot and cold cutting methods, offering unparalleled flexibility for diverse materials such as plastics and textiles. Our Hot & Cold Cutting Machine is engineered to deliver clean, precise cuts, making it an indispensable tool in manufacturing processes. This dual cutting machine embodies the essence of advanced cutting technology, ensuring efficiency and quality in production while meeting the highest industry standards. Experience the power of innovation with a high-precision cutting machine designed to enhance precision and streamline your manufacturing workflows. Invest in the future of production technology with our Hot & Cold Cutting Machine. Stay at the forefront of efficiency and quality in your industry by incorporating this essential apparatus into your industrial cutting solutions. Discover the transformative capabilities of our multi-functional cutting machine, setting new standards for clean and accurate cuts in the production of a wide range of products. Whether you need versatile cutting solutions or require a machine that adapts to various materials, our Hot & Cold Cutting Machine guarantees superior performance. Upgrade your manufacturing processes today with this innovative cutting technology that ensures efficiency and quality across all applications.

Key Features:

- Dual Cutting Capability: Combines hot and cold cutting methods for versatility.

- Precision Engineering: Delivers clean, precise cuts across various materials.

- Advanced Technology: Ensures high efficiency and quality in manufacturing.

- Multi-Functional Design: Suitable for plastics, textiles, and more.

- User-Friendly Interface: Easy to operate and integrate into existing workflows.

Benefits

- Enhanced Productivity: Streamlines manufacturing processes, reducing downtime.

- Cost Efficiency: Minimizes waste and maximizes resource utilization.

- Versatility: Adapts to different materials, making it ideal for diverse applications.

- High-Quality Outputs: Meets industry standards for precision and reliability.

- Future-Proof Investment: Keeps your operations at the forefront of cutting technology.

Models

Connect with us instantly on WhatsApp for prompt support and boost your productivity with JackFang!

Connect with us instantly on WhatsApp for prompt support and boost your productivity with JackFang!

Videos

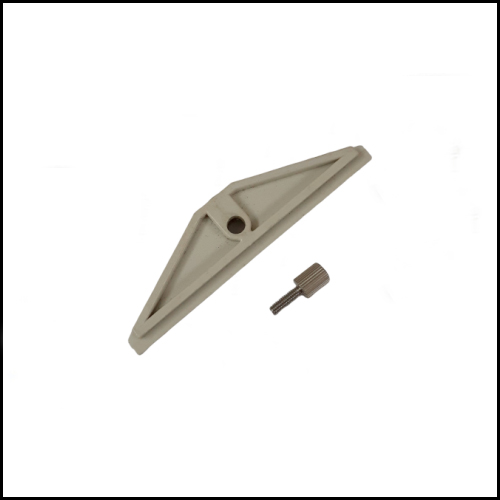

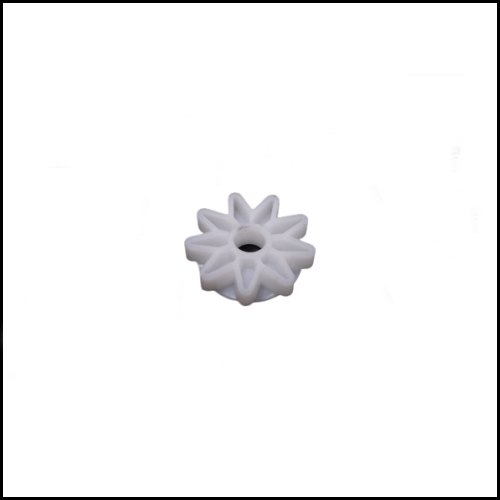

Spare Parts

Best Sellers

Top Rated Product

In a professional context it often happens that private or corporate clients corder a publication to be made and presented.